Research Interests

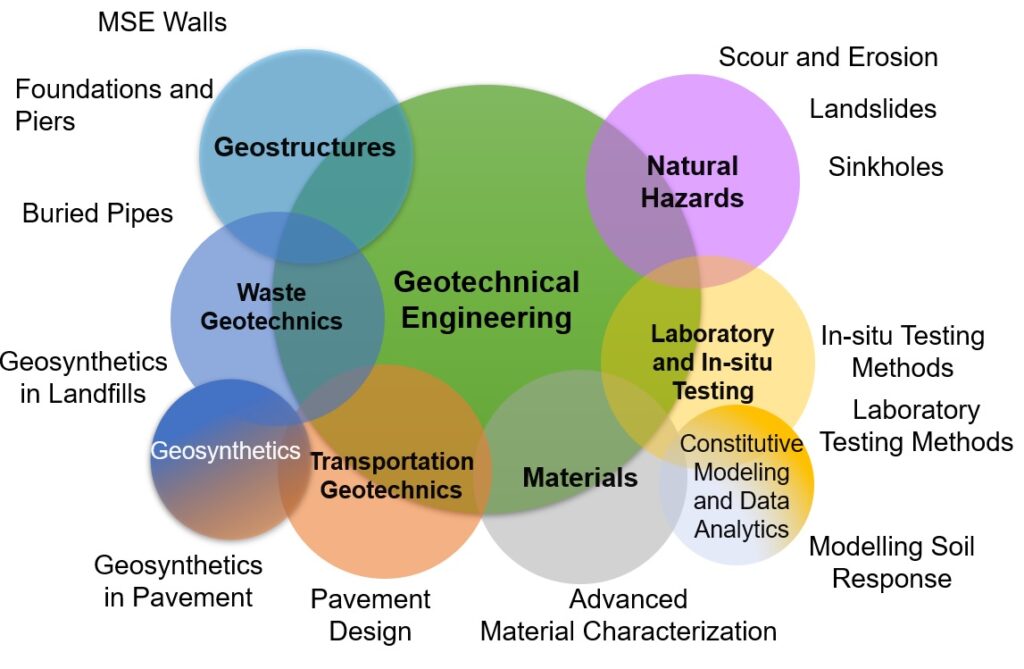

My research group plans to focus on a wide array of research in Geotechnical Engineering to serve the needs of the industry as well as the advancement of knowledge. The chart below summarizes the focus areas including classical Geotechnical Engineering and advanced interdisciplinary Geotechnical research.

Research Background

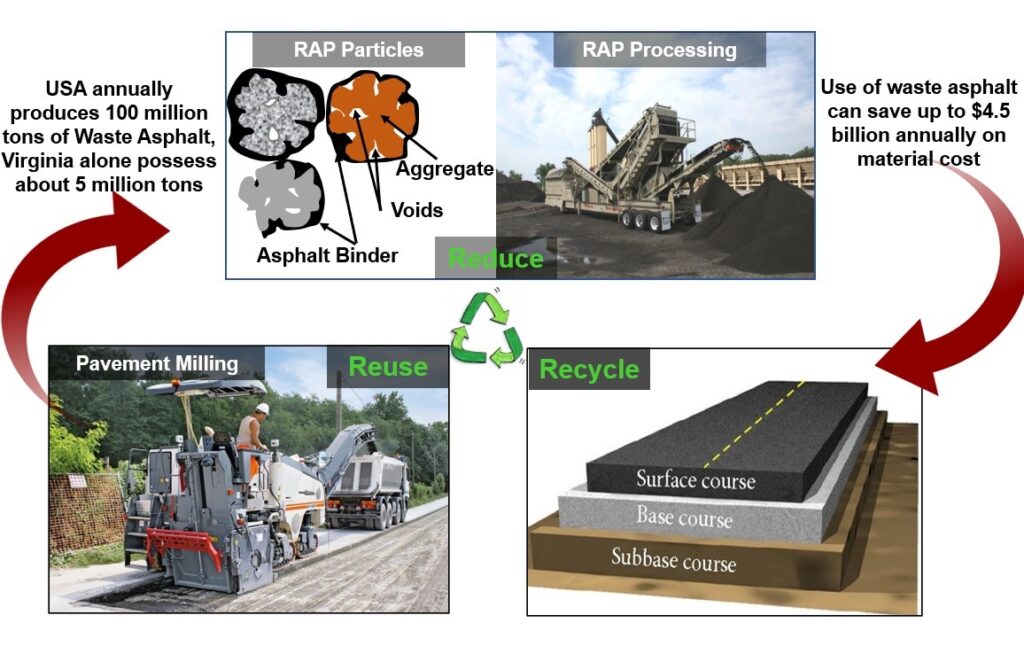

Dr. Saad Ullah is a Geotechnical Engineer with a strong background in the advanced characterization of materials, pavement design, development of performance predicting models, use of geosynthetics in embankments, and novel in-situ testing techniques. His Ph.D. research aimed at recycling reclaimed asphalt pavement (RAP) as base course material.

1). RAP is a heterogenous viscoelastic material whose properties differ invariably in comparison to virgin aggregate (VA).

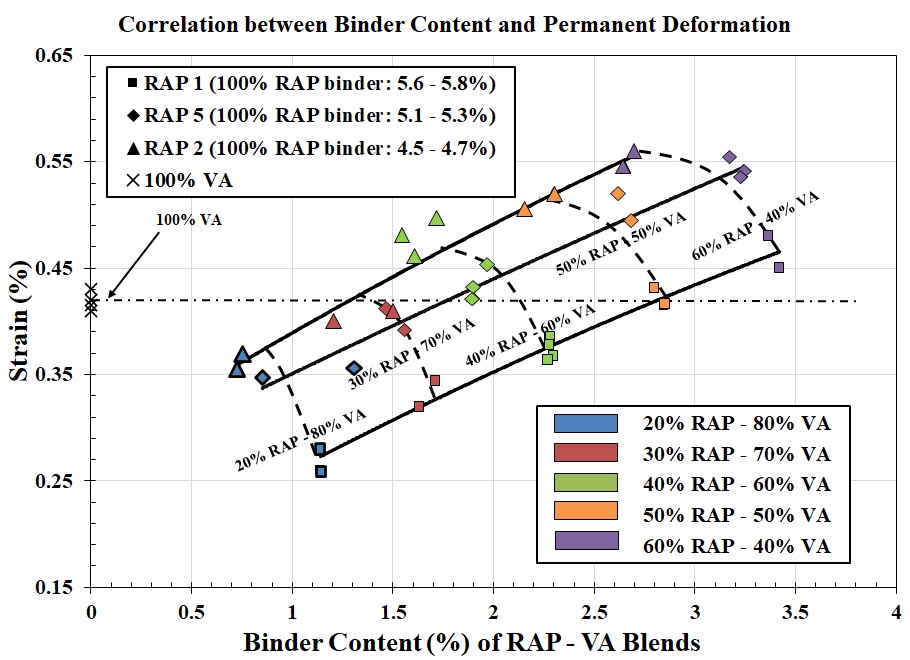

Solution: This problem can be solved by characterizing RAP from different locations and identifying variability in the properties of the collected RAP samples. Representative RAP samples can be used to create RAP-VA blends and tested in the laboratory to observe the performance. This concept was applied to evaluate the performance of RAP-VA blends under traffic type loading and relationships between the performance of the RAP-VA blend and the properties of RAP were developed.

The focus of the research was to provide a methodology that can take factors affecting the performance of RAP into account and develop a means to evaluate the performance of RAP-VA blends to create thresholds that will result in performance criteria that is no less than the performance of the VA base course. The performance evaluation in this study was conducted on the basis of Resilient Modulus and Permanent Deformation tests as previous studies show that these methods are also used to evaluate the performance of the VA considered in road construction. Additionally, results obtained from these tests were compared against the trends observed from the California Bearing Ratio test to provide some guidance for quick evaluation for the practical implications. Refer to Ullah and Tanyu [2019] for more details and implementation guidelines.

2). Conventional pavement design methods such as the Mechanistic-Empirical Pavement Design Guideline (MEPDG) do not accommodate recycled materials because the performance models used in the design process were developed using historical performance data of VA. RAP as a base course has not been used extensively by the state DOTs which is why historical performance data is not available.

Solution: The unavailability of historical data was one of the biggest challenges when it comes to the design of the base course layer using RAP-VA blends. This problem was solved by developing performance-based criteria for RAP-VA blends so that performance of RAP-VA blends can be compared to VA. The comparison between the performance of RAP-VA blends and VA allowed us to determine the optimum percentage of RAP below which RAP-VA blends tend to behave similarly to that VA. Using that threshold RAP content, the design of the RAP-VA blend as the base course can be achieved by following conventional design guidelines. However, this solution limits the RAP content that can be recycled as base course material. The concept of threshold RAP content can hinder the ability to maximize the usage of RAP. To solve this problem, Dr. Ullah has developed a mechanistic base course layer design that does not require historical performance data for design.

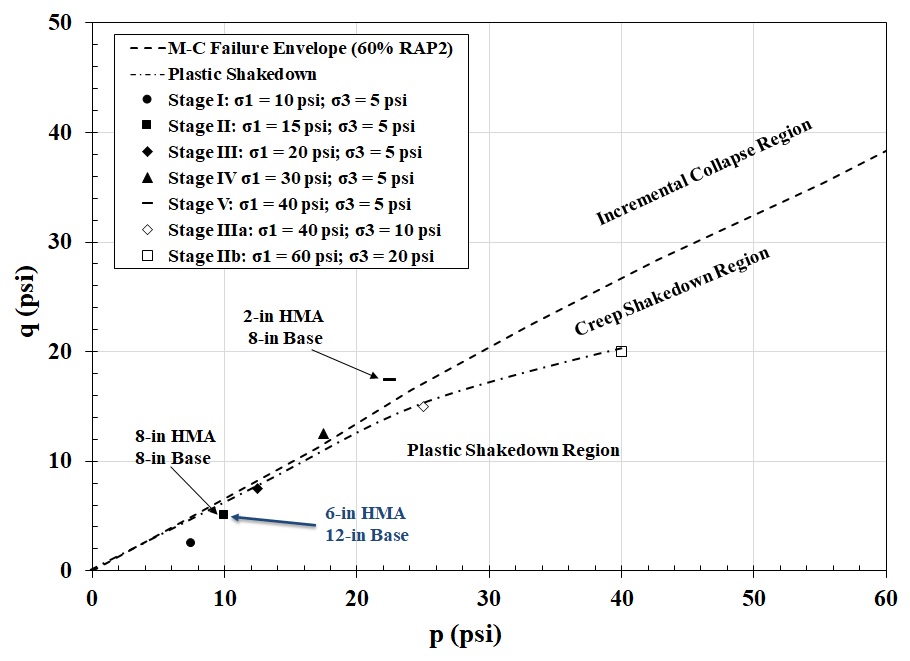

This study has focused on evaluating the suitability of the shakedown theory for the design of pavement structures with different asphalt and base course thicknesses where the unbound base course is constructed with recycled material such as RAP blended with VA. In the case of recycled materials, the design of the structures will have to incorporate the effects of plastic deformations as the addition of RAP into VA changes the behavior from that of conventional aggregate material. In the case of 100 %VA, the material may behave resiliently under loading simulative of in-situ pavement stresses but with the addition of RAP, modeling behavior based only on the material’s resilient response is not realistic. The application of shakedown theory is envisioned

as an approach to provide a mechanistic design procedure to overcome this issue. The details of the research have been presented in Ullah and Tanyu [2019], Tanyu et al. [2021], and Ullah et al., [2022].

3). Conventional quality control methods like Nuclear Density Gauge provide false data in the case of RAP due to the presence of an asphaltic binder. Hence new quality control techniques or methods need to be explored.

Solution: Several quality control methods including Light Weight Deflectometer (LWD), Falling Weight Deflectometer (FWD), Geoguage, and Dynamic Cone Penetrometer (DCP) has been tested and compared to select the most suitable and inexpensive method for statewide implementation. Large-scale model experiments, as well as Field Scale Tests, were performed and LWD was recommended as the most suitable quality control method. The results of the study were published in the TRB article Akmaz et al. [2020] and VTRC report [2021].